Innovative Technology

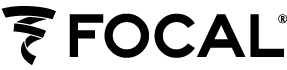

Polyglass Cone

Polyglass technology, exclusive to Focal, consists in applying molten glass microballs on a cellulose pulp cone. This process combines an excellent paper damping with glass rigidity. The rigidity index exceeds even that of a single skin Kevlar® and is almost ten times superior to one of polypropylene.

The mass/rigidity/damping ratio adjustment results in outstanding linearity of the frequency response curve, all from the inherent design of the cone. This innovation also greatly increases definition in the midrange.

The mass/rigidity/damping ratio adjustment results in outstanding linearity of the frequency response curve, all from the inherent design of the cone. This innovation also greatly increases definition in the midrange.

Crossblock

This crossover combines the advantages of a tailored crossover with 4480 adjustment points for greater flexibility and precise tuning. The highest quality components inside this crossover fully reflect the Utopia Be approach and its goal of exceptional musicality, no matter what difficulties the vehicle’s interior may present.

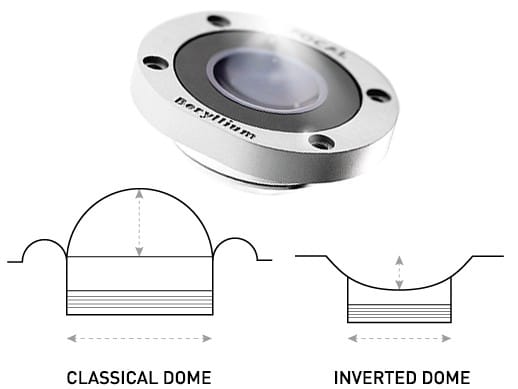

"W" Composite Sandwich Cone

The “W” composite sandwich cone permits total optimization of the frequency response curve, thanks to the total control of three key parameters: lightness, rigidity and damping. At Focal, the letter “W” means Glass/ Glass, as it usually has two sheets of woven glass tissue that are “sandwiched” onto the structural foam core. The glass tissue benefits from the incredibly fine weaving of very long fibres. This choice offers a mass and a size clearly inferior to those in Aramid fibers or other Kevlar® fabrics, which generate coloration in the midrange. It’s also important to note that the molecular bond between the resin and the glass is greater than that obtained with Aramid fibres. The cone structure is more homogeneous and its behavior in flex is much more superior.

These unique characteristics of lightness and rigidity provide control of the signal transmission speed inside the material. Adjusting the thickness of the structural foam allows a very precise control of the “W” cone’s damping. The variation of the number of glass fibre sheets and the thickness of the central foam can easily optimize the cone’s behaviour according to the desired frequency range.When listening, the sound of the “W” cone is entirely transparent, has an excellent phase response and has a very low disortion rate (rigidity 20 times higher than Kevlar® or Aramid fibre).

These unique characteristics of lightness and rigidity provide control of the signal transmission speed inside the material. Adjusting the thickness of the structural foam allows a very precise control of the “W” cone’s damping. The variation of the number of glass fibre sheets and the thickness of the central foam can easily optimize the cone’s behaviour according to the desired frequency range.When listening, the sound of the “W” cone is entirely transparent, has an excellent phase response and has a very low disortion rate (rigidity 20 times higher than Kevlar® or Aramid fibre).

Direct FET

Direct Fet® technology optimises the amplifier’s heat management. This technology helps reduce the overall temperature of the MOSFET components, thanks to the optimisation of their electrical and thermal resistance.

Actually, everything takes place in the casing of the component: thanks to a specific design, heat is dissipated via the aluminium heat sink and also via the chassis. This gives the advantage of obtaining more power in a confined space, making it possible to combine integration and sound quality.

The use of low-noise operational amplifiers considerably reduces distortion. To be more specific, this means increased musicality and enhanced precision.

The use of low-noise operational amplifiers considerably reduces distortion. To be more specific, this means increased musicality and enhanced precision.

Tweeter Technology

Aluminum / Magnesium Tweeter

Magnesium possesses great damping qualities, Aluminum great rigidity and the two in alloy can greatly reduce distortion. This unique marriage of metals offers several advantages. The impulse response is incredibly rapid yet benefits from a very short settlement time and excellent damping. This enables the tweeter to extend its frequency response beyond 28kHz (-3dB)…

This configuration produces a precise, analytical sound and an extremely deep soundstage. The frequency response curve linearity is also remarkable in that it ensures perfect neutrality. When listening, the treble frequencies are dynamic and detailed. The Aluminum/Magnesium inverted dome tweeter then combines perfectly with the Polyglass woofer in a perfect tone synergy.

This configuration produces a precise, analytical sound and an extremely deep soundstage. The frequency response curve linearity is also remarkable in that it ensures perfect neutrality. When listening, the treble frequencies are dynamic and detailed. The Aluminum/Magnesium inverted dome tweeter then combines perfectly with the Polyglass woofer in a perfect tone synergy.

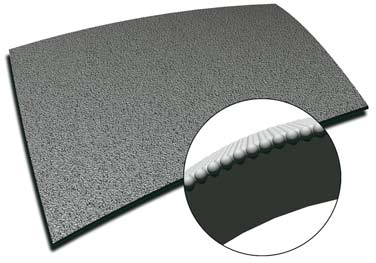

Inverted Dome Tweeter

The particular advantage of the inverted dome tweeter of our Studio Monitors is the optimization of the mechanical coupling between the voice coil and the dome. The voice coil is fixed at mid-height on the dome and uniformly moves the cone entire surface. The positive dome is only joined at its edge, causing it to be inactive beyond 16kHz for a flexible surface. The inverted dome directly radiates into the air, with maximum efficiency, which is translated by an extremely precise soundstage. The dome’s response curve is clearly more linear than that of any positive dome. It provides better space dispersion and very low directivity, contrary to ribbon tweeters. The inverted dome tweeter offers unequalled dynamics, enabling sound engineers to very precisely control compression.

The image precision (height, width and depth) is outstanding and makes the positioning of each element very easy, as well as allows one to exactly assess the reverb tails.

The image precision (height, width and depth) is outstanding and makes the positioning of each element very easy, as well as allows one to exactly assess the reverb tails.

Beryllium Tweeter

Focal, after two years of research and development, produced a world first: a pure Beryllium inverted dome, able to cover more than five octaves (1000Hz – 40kHz). You may ask yourself why do we strive for an extended response at 40kHz, if the human ear can only hear up to 20kHz? If you can extend frequency response, you will improve the perception of transients and other micro details. As well, the linearity of the speaker’s response curve is mainly a function of three opposite parameters: lightness, rigidity and damping.

Focal, after two years of research and development, produced a world first: a pure Beryllium inverted dome, able to cover more than five octaves (1000Hz – 40kHz). You may ask yourself why do we strive for an extended response at 40kHz, if the human ear can only hear up to 20kHz? If you can extend frequency response, you will improve the perception of transients and other micro details. As well, the linearity of the speaker’s response curve is mainly a function of three opposite parameters: lightness, rigidity and damping. To this day, only one material permits a joining of these parameters: Beryllium. For domes with identical masses, Beryllium is seven times more rigid than Titanium or Aluminum, the latter two well known for their rigidity. This results in a sound wave propagation three times faster than Titanium and two and a half times faster than Aluminum. In the end, the linearity of the frequency response curve, the acoustic transparency and the impulse response of the Beryllium tweeter are maximized and offer near-perfect sound.

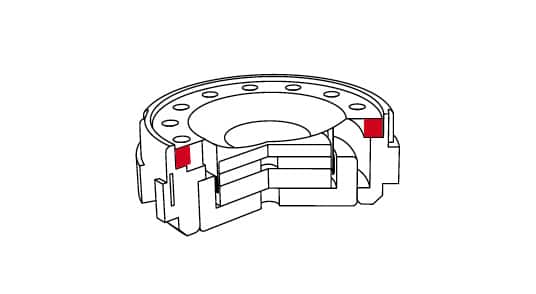

The TNF Tweeter

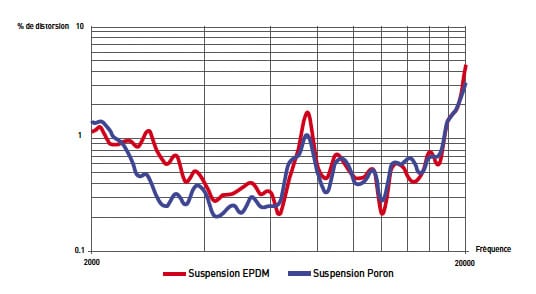

Focal brand’s signature product, the inverted dome tweeter has been continually developed ever since it was created. It bears repeating that its main advantage, apart from its very low directivity, lies in its use of a coil of small diameter (hence very light and better accelerating) directly fixed to the rigid dome.Just as with the cones of its bass and midrange speaker drivers, what makes Focal unique is working directly on the sound output and, therefore, on the mechanical characteristics of materials. When we introduced the pure Beryllium inverted dome tweeter ten or so years ago, we clearly demonstrated the decisive advantage of this exclusive technology.For the TNF tweeter, we have brought two major evolutions to our aluminium/magnesium tweeter. The suspension between the dome and its bracket uses Poron, a material with shape memory.This suspension method is directly derived from the famous Utopia Beryllium tweeter, making it possible to reduce distortion by a factor of three in the 2-3 kHz range, where the human ear has very great sensitivity.

The inverted dome’s spatial characteristics and very low directivity already make it greatly superior to the conventional domes used by our competitors and to further improve this a wave guide has been developed. In a horizontal plane, its frequency response has a variance of +/- 0.5 dB. This performance guarantees an incredibly stable sound stage which makes the listening position much less critical.

It is due to more than twenty years dogged work on our manufacturing processes that it is possible to achieve such precision in a component as delicate as a tweeter.

Control over production is the one and only solution for continued innovation when it comes to loudspeakers...

The inverted dome’s spatial characteristics and very low directivity already make it greatly superior to the conventional domes used by our competitors and to further improve this a wave guide has been developed. In a horizontal plane, its frequency response has a variance of +/- 0.5 dB. This performance guarantees an incredibly stable sound stage which makes the listening position much less critical.

It is due to more than twenty years dogged work on our manufacturing processes that it is possible to achieve such precision in a component as delicate as a tweeter.

Control over production is the one and only solution for continued innovation when it comes to loudspeakers...

Cross-section of the TNF tweeter

Poron’s physical properties provide improved control over the mobile assembly in the magnetic parts.

Distortion levels directly affect sound quality

The use of Poron has reduced the distortion by half in the tweeter’s. Bandwidth between 2–4 kHz: an area where the sensibility of the ear is very high.

Flax Cone Technology

Made in France but affordable, Flax cones are oriented towards acoustic performance, high-tech and give an original design to the brand’s speaker drivers!

After more than five years of research and development, engineers at Focal can now reveal a new cone made of high-quality flax fibers. F cone are characterised by their natural sound, with low coloration, their richness of reproduction in the midrange register and their tighter bass.

Unique Qualities of Flax

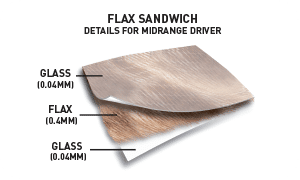

F cones are made of high-quality flax fibers core enclosed by two thin layers of glass fiber. They satisfy the key criteria of a high performance diaphragm: high internal damping, high velocity of sound, and high flexural rigidity.Rigidity

All these criteria cannot be met by a mono-material cone. Sandwich technology greatly influences the neutrality of the sound produced by the cone, something, which has always been Focal’s hallmark. The expertise gained from the sandwich technology of the Utopia and K2 Power ranges enabled Focal to develop a revolutionary flax-fiber cone conciliating the 3 criteria.Lightness

Flax is twice as light as fiberglass, because the fiber is hollow. It also has very low elasticity which makes it ideal to increase the flexural rigidity of a sandwich structure. Moreover, it can be obtained in non-woven bundles of considerable diameter and it can therefore produce the thickness required for a sandwich.

Flax is twice as light as fiberglass, because the fiber is hollow. It also has very low elasticity which makes it ideal to increase the flexural rigidity of a sandwich structure. Moreover, it can be obtained in non-woven bundles of considerable diameter and it can therefore produce the thickness required for a sandwich.Internal Damping

Composite materials have properties suitable for applications where both rigidity and low mass are required. However, their disadvantage is that they lack damping, which leads to very poor control of vibrations.Recent developments in this field combining composites and natural fibers have brought unexpected opportunities. Flax fiber has an excellent internal damping of the same order of magnitude as the glass or Kevlar fibers or aluminum.

Made in France and Affordable

Flax cones are designed and manufactured in France, from french flax fiber. France is the main cultivator in Europe of fiber flax, principally in Flanders, Picardy, Normandy and the Pas-de-Calais region. French flax is considered the best in the world.

Flax cones are designed and manufactured in France, from french flax fiber. France is the main cultivator in Europe of fiber flax, principally in Flanders, Picardy, Normandy and the Pas-de-Calais region. French flax is considered the best in the world. Synthetic fibers or foams originating from petrochemical resources are subject to inflation linked to the sharp rise in crude oil prices. Organic or ecological textiles, like flax, are thus becoming more and more price competitive.

Because the “W” or "K2" sandwich have to be manufactured by hand, their range of application remains limited for reasons of cost. The industrial process developed to manufacture the "F" cones bring it within reach of very price competitive product ranges